The past two weeks could not have been more different. Last week, Cincinnati’s working-class vibe; this week, Las Vegas’ glitz. The nuts and bolts of product design with a smattering of vision versus a lot of vision with the barest mention of product design. We’ll get to Las Vegas and the Dassault Systèmes 3DEXPERIENCE in a post later but first, we need to come to grips with Siemens’ 2013 NX CAE Symposium.

This was a world of Young’s modulus, Poisson’s ratio, math-on-the-projector, and correlation between simulation and test. We heard from CAE practitioners about their projects and saw, for the first time, how Siemens intends to integrate the recent LMS acquisition into its CAE portfolio. There’s a lot to cover, so let’s get to it.

Dave Shook, SVP & Managing Director, Americas, Siemens PLM Software led off with a very strong strategy statement:

[Siemens is intent on] “providing open simulation, test and services to drive product performance decisions across the complete product lifecycle [and] enabling systems driven product development with closed-loop performance verification to deliver faster product engineering iterations, enterprise-wide visibility to simulation results and knowledge [and] increased confidence that products will meet functional requirements.”

It’s a mouthful, but there are a couple of key points that were elaborated on in the company presentations that followed. First, Siemens realizes that its customers use other commercial, open source and in-house products and that its architecture must be open to be truly useful and for NX to be integrated into the product development process. Second, Teamcenter plays a crucial part in the CAE vision, managing virtual/physical test processes and in serving these results out to the greater project tea. Finally, one cannot undersell the importance Siemens and its customers place on the integration of LMS’ test suite — the question isn’t if, but how quickly can that integration take place.

Other Siemens presentations covered the importance of systems-level and multi-domain simulation, model management, spanning 1-D conceptual modeling to full-up 3D simulation, multi-body dynamics with Virtual.Lab Motion and test-based engineering initially in noise, vibration and durability with Test.Lab.

Siemens’ Jim Rusk talked about the roadmap, combining the best of LMS and NX — and there’s actually very little overlap. Siemens is going to leverage LMS’ Virtual.Lab and Samtech for acoustics and vibration; mechanisms and durability; process integration for automotive and aerospace; and wind turbine analysis. NX CAE and NX NASTRAN will be targeted at space and electronics systems cooling; design and motion simulation; structural, thermal and flow analysis; and simulation data/process management.

The biggest question, of course, was about the timeline for bringing Virtual.Lab from the CATIA V5 platform to NX. Mr. Rusk said it wasn’t an easy job and that it would take six years; the first modules should be out in 2014. Mr. Rusk also said that Teamcenter will not be required, though it is suggested to manage data and processes.

The academic and customer presentations were an interesting mix of tactical and strategic. CAE-focused events are typically very tactical with lots of equations and simulation AVIs. Since Teamcenter is a big part of Siemens’ overall offering, the NX CAE Symposium often operated at a higher level, with speakers covering how they use simulation as a collaboration tool, share results between design teams and cut design cycle time.

What’s interesting is how Siemens is approaching the common problem of better products, to market faster. For years, industry had moved toward virtual testing as a way of saving money and time, and reducing its reliance on instrument-and-break processes. The LMS acquisition put the focus squarely back on testing, recognizing that we aren’t, in general, comfortable enough with our digital technology to eliminate the physical. There will always be new materials, products, and use cases, but I can’t help wonder when our comfort levels and expertise with the failure modes of earlier product iterations will allow us to cut the test volume. Siemens is betting it’s not soon, and I think they’re right.

Quite a few of the attendees I spoke with at the Symposium knew NX but weren’t familiar with LMS and more than a few didn’t know much about either — it was an interesting mix. By the end of the two-day session, awareness of LMS was definitely much higher and I know a number of the attendees were planning to discuss their test strategies back at the office, with a view towards bringing in some LMS even before it is integrated into NX.

It’s always fascinating to learn about the obstacles faced by the designers and manufacturers of products we don’t think about, yet use every day. Space projects are cool and failure is truly not an option, but more mundane objects have their challenges, too.

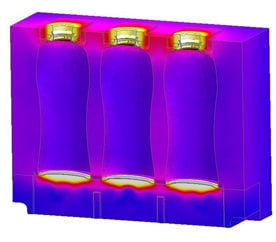

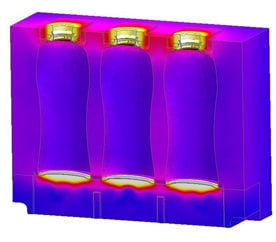

This video, produced by Siemens, gives a snapshot of the talk by Graham Packaging’s Ed Roubal & Travis Hunter. My takeaways: Blue plastic isn’t the same as white; someone worked hard to make that detergent bottle hold up to forming, filling and the rough handling it has to take on the way to the laundromat.

Once again, I’m reminded how much I take for granted and how hard someone worked to keep me safe (and hydrated, in clean clothes). There are so many ways to approach any problem, try to get to root cause, and combine virtual and physical methodologies to best effect. The speakers at the NX CAE Symposium shared their best practices and left the audience with a lot to take back and think about. You can see some of the presentations

here

—

Dean Teik Lim of the University of Cincinnati College of Engineering and Applied Science told us that school has had a co-op program since 1906, helping generations of students “integrate theory and practice”. Co-op programs only work when employers get involved; if you need help and can mentor a student, consider hiring a co-op.

Note: Siemens graciously covered some of the expenses associated with my participation at the event but did not in any way influence the content of this post.

Images courtesy of Siemens.

Related

Discover more from Schnitger Corporation

Subscribe to get the latest posts sent to your email.

Once again, I’m reminded how much I take for granted and how hard someone worked to keep me safe (and hydrated, in clean clothes). There are so many ways to approach any problem, try to get to root cause, and combine virtual and physical methodologies to best effect. The speakers at the NX CAE Symposium shared their best practices and left the audience with a lot to take back and think about. You can see some of the presentations here

—

Dean Teik Lim of the University of Cincinnati College of Engineering and Applied Science told us that school has had a co-op program since 1906, helping generations of students “integrate theory and practice”. Co-op programs only work when employers get involved; if you need help and can mentor a student, consider hiring a co-op.

Note: Siemens graciously covered some of the expenses associated with my participation at the event but did not in any way influence the content of this post.

Images courtesy of Siemens.

Once again, I’m reminded how much I take for granted and how hard someone worked to keep me safe (and hydrated, in clean clothes). There are so many ways to approach any problem, try to get to root cause, and combine virtual and physical methodologies to best effect. The speakers at the NX CAE Symposium shared their best practices and left the audience with a lot to take back and think about. You can see some of the presentations here

—

Dean Teik Lim of the University of Cincinnati College of Engineering and Applied Science told us that school has had a co-op program since 1906, helping generations of students “integrate theory and practice”. Co-op programs only work when employers get involved; if you need help and can mentor a student, consider hiring a co-op.

Note: Siemens graciously covered some of the expenses associated with my participation at the event but did not in any way influence the content of this post.

Images courtesy of Siemens.